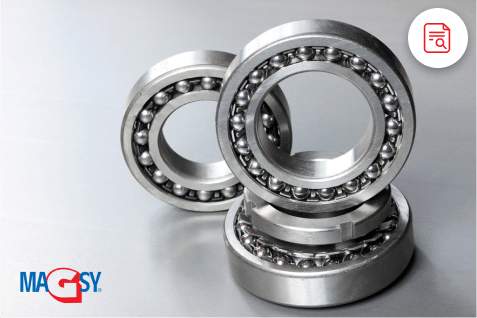

A magnetic separator is a device that uses a magnetic field to separate magnetic materials from non-magnetic materials. Magnetic separators are used in a variety of industries including mining, metallurgy, waste processing and food processing. This tool is very important for the effective separation of different types of materials based on their magnetic properties.

There are a number of different variations of magnetic separators, which differ in size, shape, the type of magnetic field used and the way the material passes through the separator. The most common types are hand-held magnetic separators. These separators are small and easily portable, allowing them to be used in smaller spaces, for example to separate scrap metal.

Please describe your needs as precisely as possible. We will send you a confirmation of your request and redirect you to a suitable specialist. He or she can contact you for further details at the contacts listed.