- Miscellaneous metal waste – collection tests MM 1200 DM - 50012

- Miscellaneous metal waste – collection tests MM 1200 DM-UP 50015

- Miscellaneous metal waste – collection tests MM 1200 DM-UP N 50071

- Miscellaneous metal waste – collection tests MM 1200 DM-UP2 - 51480

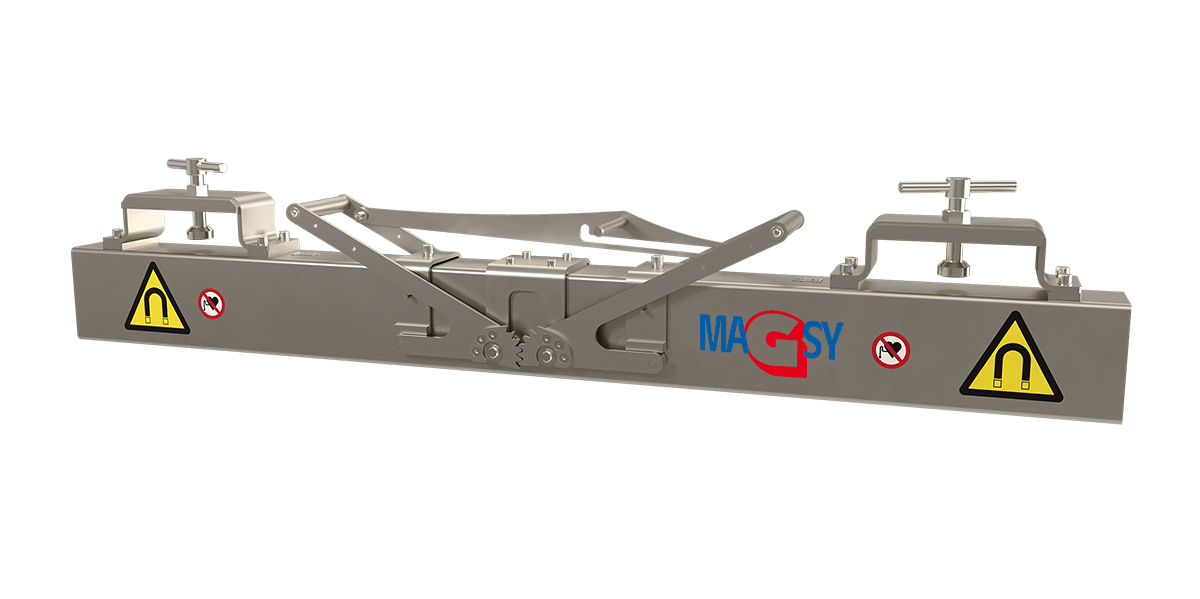

Magnetic broom (magnetic sweeper) for the forklift truck MM 1200 DM

We have developed a magnetic broom/sweeper destined for forklift trucks. This broom/sweeper can be easily positioned onto forklift truck skids. It is especially designed for metal impurities (strips, nails, grinding dust...) collection. It finds its application also in cleaning of huge areas.

We have developed a magnetic broom/sweeper destined for forklift trucks. This broom/sweeper can be easily positioned onto forklift truck skids. It is especially designed for metal impurities (strips, nails, grinding dust...) collection. It finds its application also in cleaning of huge areas.

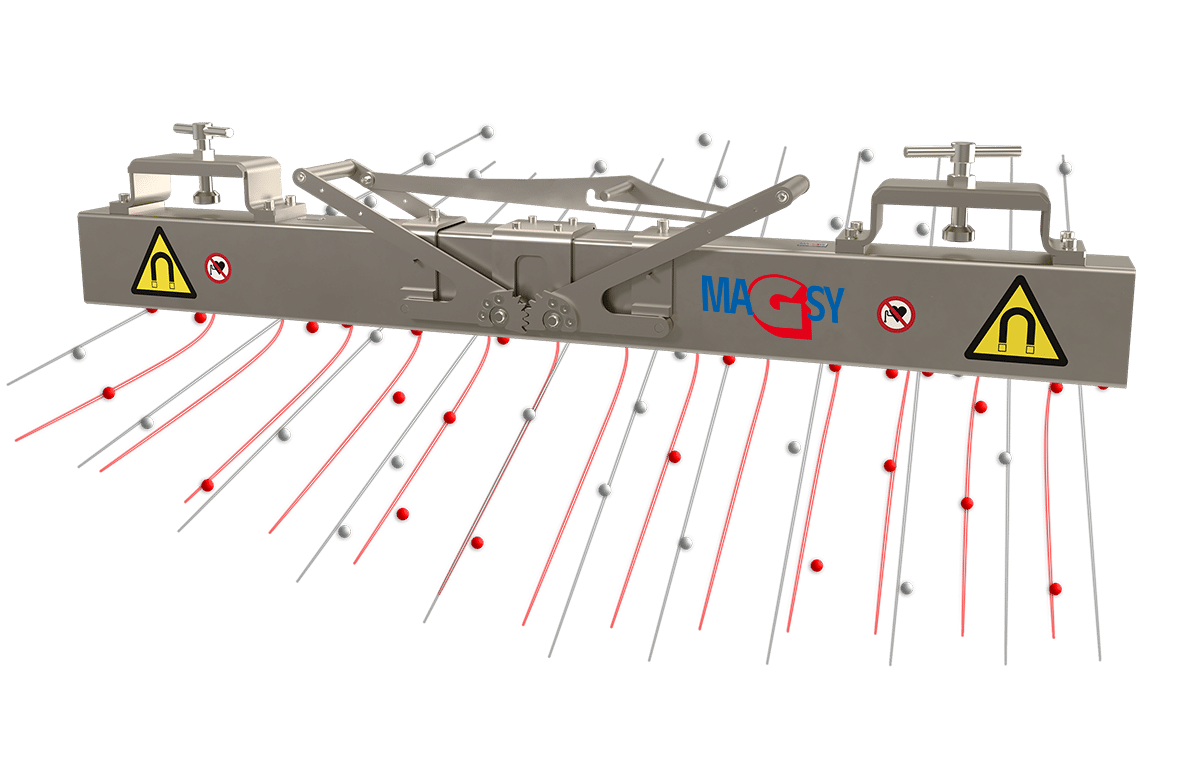

Magnetic sweeper cleaning

By pulling out the handrail to the upper part of the magnetic lash, the lower part becomes de-magnetized so the metal particles are released.

Main benefits

- Magnetic area width: 1200 mm

- Simple cleaning

- Possibility of using on various types of surfaces

- Storage capability

Demonstrations of sweeper using

Miscellaneous metal waste – collection tests

| MM 1200 DM 50012 |

Distance from the surface | ||

| 30 mm | 50 mm | 80 mm | |

| Lifted object | Collection success rate | ||

| Small office clip (0,3 g) | 100 % | 100 % | 100 % |

| Steel splinter (1,4 g) | 100 % | 100 % | 10 % |

| Self-tapping screw 4x60 (2,8 g) | 100 % | 100 % | 80 % |

| Self-tapping screw 5x80 (6 g) | 100 % | 100 % | 40 % |

| Pad 5 (0,3 g) | 100 % | 90 % | 0 % |

| Pad 8 (1,5 g) | 100 % | 90 % | 0 % |

| Pad 10 (2,9 g) | 100 % | 90 % | 0 % |

| Nut M5 (1,1 g) | 100 % | 20 % | 0 % |

| Nut M8 (4,6 g) | 100 % | 10 % | 0 % |

| Nut M10 (10 g) | 100 % | 10 % | 0 % |

| Screw M6x10 (4 g) | 100 % | 20 % | 10 % |

| Screw M8x20 (11,8 g) | 100 % | 60 % | 0 % |

| Screw M10x55 (37,4 g) | 100 % | 70 % | 0 % |

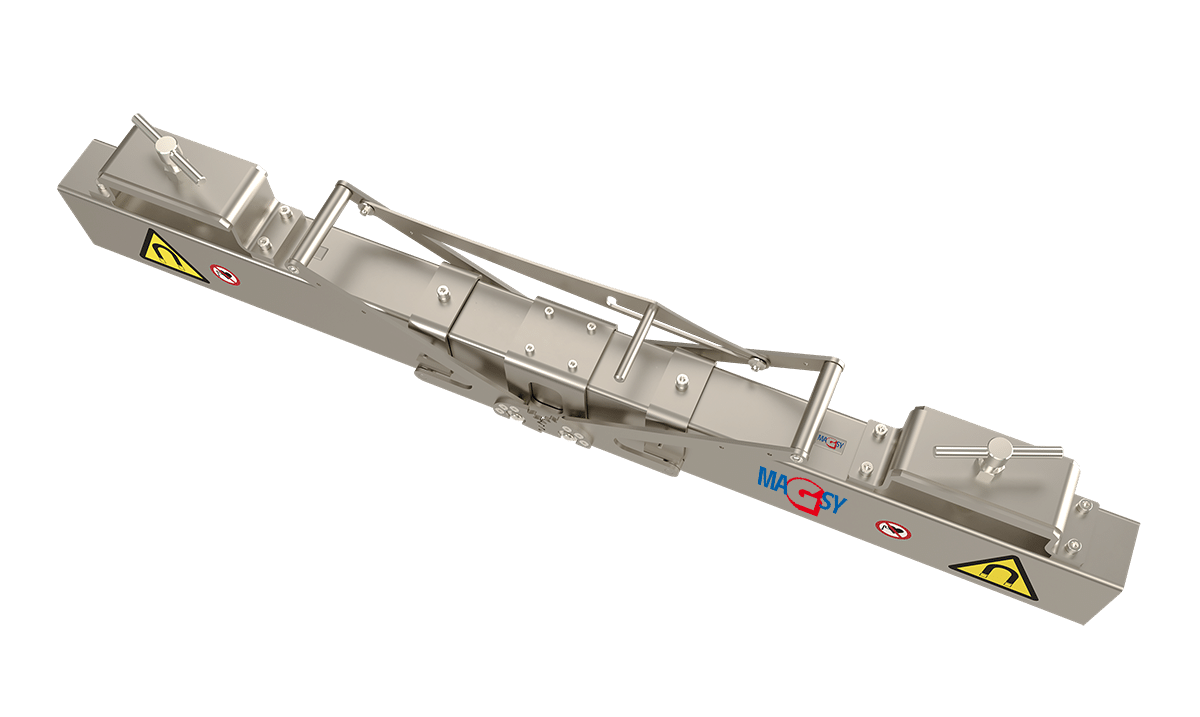

Magnetic broom for the forklift truck MM 1200 DM - UP

This magnetic broom is, in comparison with the model MM 1200 DM, made of a stainless steel so it has a higher resistance, it is more comfortable to de-magnetize and easier method of fixation onto a forklift truck. From a viewpoint of magnetic efficiency, both brooms are identical.

How the broom (sweeper) can be cleaned?

By lifting up of both levers the broom is de-magnetized so caught metal particles fall off.

Benefits

- Easy handling

- Simple cleaning – lever mechanism

- Magnetic area width: 1200 mm

- Stainless-steel version

- Easy fixation onto forklift trucks

Both brooms (sweepers) can be adapted to a desired length based on the forklift truck type.