Plate magnetic separator - manual cleaning (MSP)

These are intended for separation from easily permeable mixtures with worse pouring properties and higher grain size, which would not fall down continuously through the above described magnetic grids. In their standard modification, they are fitted with ferritic magnets and if required, we can deliver them also in a modification fitted with rare-earth (NdFeB) magnets. We produce the plate magnetic separators with the incoming hole diameter of 100, 150, 200 and 250 mm.

These are intended for separation from easily permeable mixtures with worse pouring properties and higher grain size, which would not fall down continuously through the above described magnetic grids. In their standard modification, they are fitted with ferritic magnets and if required, we can deliver them also in a modification fitted with rare-earth (NdFeB) magnets. We produce the plate magnetic separators with the incoming hole diameter of 100, 150, 200 and 250 mm.

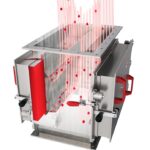

Structure of the bulk mixture separator

The adjustable spreading roof is a great advantage of this type; the roof may be used to to route material directly towards the magnetic boards, achieving thus effective magnetic separation as much as possible even if installation is performed under a certain angle.

The adjustable spreading roof is a great advantage of this type; the roof may be used to to route material directly towards the magnetic boards, achieving thus effective magnetic separation as much as possible even if installation is performed under a certain angle.

Plate magnetic separator - manual cleaning - (MSP UP)

We keep on trying to improve our products and make them even better than ever before. In terms of this philosophy, we started to produce a desk-type separator, which can be - due to its unique demagnetizing system - much more easily and faster cleaned from the accumulated magnetic impurities. This leads to time savings and production efficiency improvements.

From its function and height points of view, this type of separator is identical with the above mentioned separator so it is possible to replace it with a new model, without a need of any modifications. Also, it is equipped with a combing roof and ferrite magnets.

Animation of the plate magnetic separator functioning

Plate magnetic separator - manual cleaning (MSP UP2)

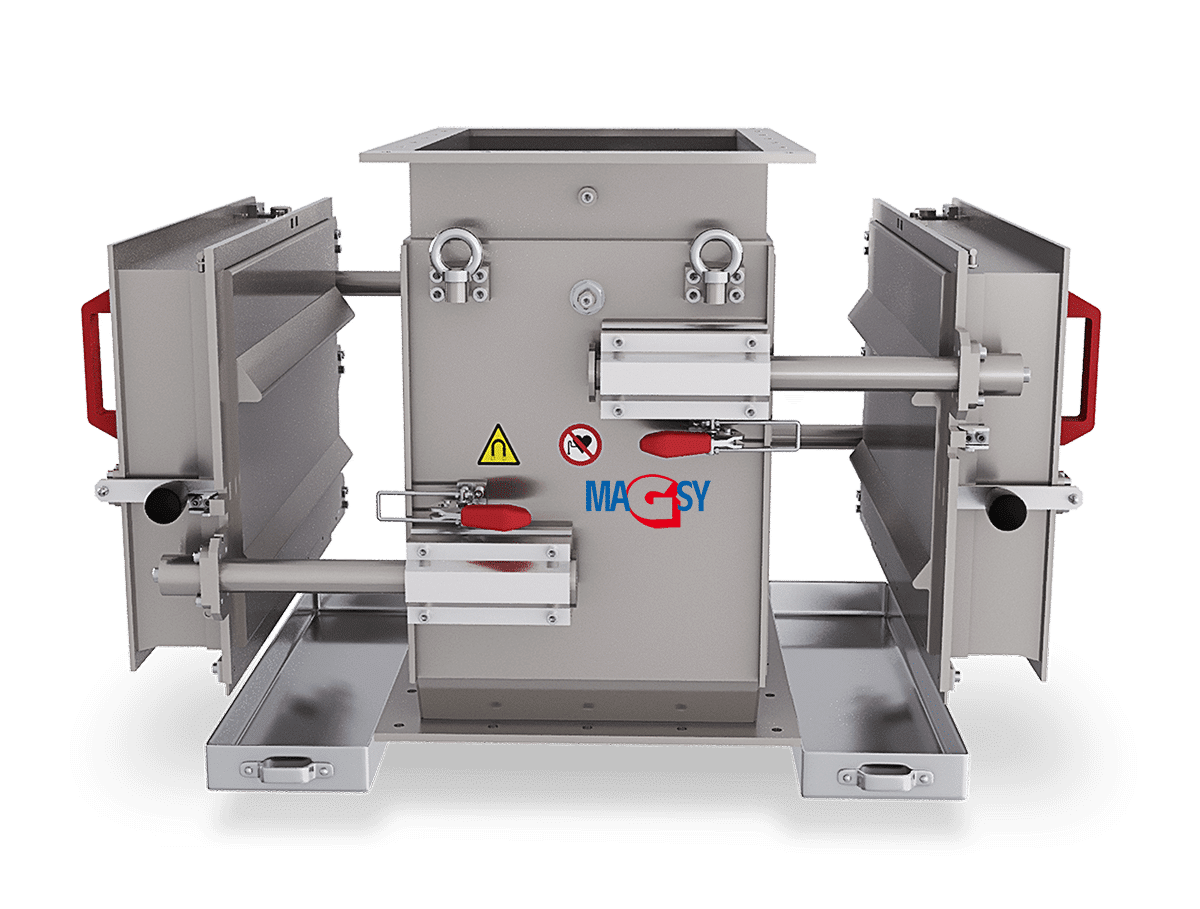

Plate magnetic separator - automatic cleaning (MSP FAC)

Magnetic separator cleaning is controlled pneumatically. The separator is suitable for the separation of metal particles from materials with complicated bulk properties and coarser granularity. Separated material is to be put inside through the central part. Adjustable combing roof directs material flow right to the magnetic plates; this way the most efficient magnetic separation is achieved.

Magnetic separator cleaning is controlled pneumatically. The separator is suitable for the separation of metal particles from materials with complicated bulk properties and coarser granularity. Separated material is to be put inside through the central part. Adjustable combing roof directs material flow right to the magnetic plates; this way the most efficient magnetic separation is achieved.

Plate magnetic separators are manufactured also in the version including automatic cleaning. From its function point of view, such separator is identical with manually-cleaned separators; also its building area remains the same (so it is possible to replace a manually-cleaned plate separator with an automatically-cleaned one).

Plate magnetic separators are manufactured also in the version including automatic cleaning. From its function point of view, such separator is identical with manually-cleaned separators; also its building area remains the same (so it is possible to replace a manually-cleaned plate separator with an automatically-cleaned one).

Magnetic separator cleaning

During the automatic cleaning process, the plates are moved to the sides of the separator where they become de-magnetized. As a result of this, collected impurities are automatically falling to the side spoil banks.

During the automatic cleaning process, the plates are moved to the sides of the separator where they become de-magnetized. As a result of this, collected impurities are automatically falling to the side spoil banks.

As a standard, magnetic plates are equipped with ferritic magnets. By request we can deliver you the product also equipped with rare-earth (NdFeB) magnets.

The device disadvantage consists in the necessity of material flow interruption during the automatic cleaning process.

Animation of the automatic cleaning process

These are intended for separation from easily permeable mixtures with worse pouring properties and higher grain size, which would not fall down continuously through the above described magnetic grids. In their standard modification, they are fitted with ferritic magnets and if required, we can deliver them also in a modification fitted with rare-earth (NdFeB) magnets. We produce the plate magnetic separators with the incoming hole diameter of 100, 150, 200 and 250 mm.

These are intended for separation from easily permeable mixtures with worse pouring properties and higher grain size, which would not fall down continuously through the above described magnetic grids. In their standard modification, they are fitted with ferritic magnets and if required, we can deliver them also in a modification fitted with rare-earth (NdFeB) magnets. We produce the plate magnetic separators with the incoming hole diameter of 100, 150, 200 and 250 mm. The adjustable spreading roof is a great advantage of this type; the roof may be used to to route material directly towards the magnetic boards, achieving thus effective magnetic separation as much as possible even if installation is performed under a certain angle.

The adjustable spreading roof is a great advantage of this type; the roof may be used to to route material directly towards the magnetic boards, achieving thus effective magnetic separation as much as possible even if installation is performed under a certain angle.